Rock Set Assembly

A brief snapshot of the assembly process adopted for creating the rock and mineral sets….

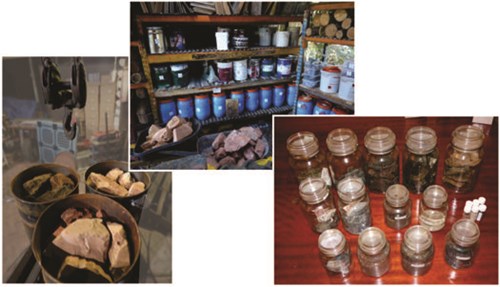

Sorting Donated Materials

The materials donated to the project come from a variety of sources. Smaller quantities of great variety are received from geologists keen to clear out their garage or rock-garden, while larger volumes of specific rock and mineral types are donated by various government and commercial organisations.

These are sorted and stored for subsequent preparation

Cleaning

Cleaning of grubby specimens is achieved by water-blasting or sand-blasting with clear glass beads or garnet; this not only works wonders in removing weathered grime, in some cases it enhances the features of the specimen. For example the crystal structure in coarser igneous rocks, or the structure of the corals in fossiliferous limestone.

Before cleaning...

After cleaning...

Treated with Paraloid 72 (described below)

Other samples required more careful cleaning, performed with rubber gloves and Sunlight soap. When higher authorities allow, a more mechanized approach can be taken, saving considerable time.

Identifying and Sorting

Sizing the Specimens

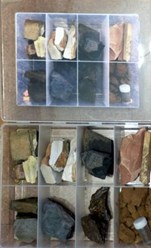

One of the key goals in the assembly of the rock sets was to provide specimens that were large enough to clearly exhibit the identifying attributes for the rock type, rather than a wafer-thin slice glued onto a cardboard cut-out of Neddy Seagoon’s North Sea quarry.

Specimen boxes have been sourced that hold eight specimens 75x75x100mm in size. (That’s 3x3x4in, or ‘fist-sized’ in the old money…) The additional benefit of this size is that they are too big for students to stick in their pockets…

The mineral specimens, being by nature more uniform, are housed in smaller containers holding 12 specimens, allowing a 50x50x75mm specimen size. (And yes, Moh’s scale of hardness only has ten members, so we added Kryptonite and Naquadria for interest).

Early on it was found that slabbing the material into 50-70mm slabs and then breaking the resulting slabs with a bolster greatly reduced the waste compared to simply breaking or crushing the large pieces. This resulted in specimens that had both a broken and a sawn face, which provided a better view of the rock structure and constituent mineralogy in many cases.

Sawn faces -

Freshly broken faces -

Some better specimens are being carefully cut into thinner presentation slabs that may be included with the sets. Again modern technology, and a forgiving wife enable the task to be achieved in a fraction of the time, and with great precision.

Some better specimens are being carefully cut into thinner presentation slabs that may be included with the sets. Again modern technology, and a forgiving wife enable the task to be achieved in a fraction of the time, and with great precision.

Following the cutting process, (diamond or reciprocating), remnant saw-marks are carefully removed to provide a superior view of the sample features.

Materials Storage

Prepared specimen materials are stored in air-tight plastic drums, again donated for the project.

Specimen Treatment

Some of the mineral and rock specimens belong to groups that can have potentially harmful varieties, examples being talc, actinolite or serpentinite. While all materials accepted are examined or have been tested to confirm this is not the case, they are treated by soaking in an archaeological polymer (Dow Corning Paraloid-72) as a precaution. This effectively binds the specimen together, preventing fraying.

Some softer porous materials are also treated in this way to improve their resistance to handling.

Where it improves visibility, one sawn face of the rock specimens are coated using a matt polyurethane coating.

Packing and Labelling

Boxes are packed by volunteers at the working bees on a regular basis.

The specimen name is provided on the label on top of each box, along with a plug for the GSA and the various sponsors who have contributed specimen materials, equipment or other services.

Petrified at the thought of applying white paint and ID numbers to the large numbers of specimens, a photograph of each set is instead fixed on the inside of the lid, removing all ambiguity.

The photography and label preparation is automated thanks to GDD’s uLog, u Snap and uCrop data management tools and utilities.

Snap and uCrop data management tools and utilities.

Dispatch

The delivery cost is the responsibility of the individual school or institution. The sample sets can be collected by the schools to save freight costs, or dispatched by courier.